For automotive technicians and shop owners tackling the complexities of modern vehicle diagnostics, especially within the Mercedes-Benz ecosystem, having the right tools is paramount. When diagnostic sessions become challenging, understanding the capabilities of your equipment, particularly when using Xentry Obd2 systems, is crucial. Mercedes-Benz vehicles, renowned for their sophisticated engineering, demand equally advanced diagnostic solutions to effectively interpret their intricate systems.

This article delves into the world of diagnostic equipment, with a spotlight on XENTRY, aiming to clarify its role and benefits for both business owners and technicians honing their skills. We will explore the evolution of the Diagnostic Link Connector (DLC) and underscore the importance of a thorough grasp of the technologies embedded within Mercedes-Benz vehicles. Our focus will remain on how XENTRY OBD2 interfaces and enhances diagnostic procedures.

Understanding OBD-II and its Evolution

The year 1996 marked a significant turning point in automotive diagnostics with the mandate of OBD-II for all vehicles sold in North America. This standardization brought with it the modern OBD II connection, known as the DLC. While the physical connector became standardized, the “proprietary” connections to vehicle subsystems remained manufacturer-specific. OBD-II was primarily designed to provide technicians, both within dealerships and independent shops, with diagnostic access to engine and transmission systems, offering a defined set of “modes” focused on emissions, testing, and basic diagnostics.

As engine management systems grew increasingly complex, the OBD-II protocol evolved to accommodate a wider array of modes and accessible data. Manufacturers are obligated to make their diagnostic protocols accessible through the DLC, encompassing protocols like CAN, VPW, PWM, and 9141-2 with ISO 14230-4. In North American vehicles, access to one or more of these protocols via OBD-II is standard. However, it’s important to note that manufacturers also utilize specific pins (terminals) within the DLC for their own proprietary functions, which are beyond the reach of standard OBD-II.

Modern OBD2 devices, when well-designed, can access significantly more data than older scan tools. However, this capability hinges on the proficiency of suppliers and software developers in accurately calculating and displaying Parameter IDs (PIDs) mandated and made available by the vehicle manufacturer. Current OBD2 tools leverage high-speed CAN for diagnostic data access.

Even with the advancements in OBD2 scan tools allowing access to the CAN structure, their access to the comprehensive electronics network of systems like engine and transmission control in a Mercedes-Benz remains limited. The data accessible through standard OBD2 is primarily confined to what regulations require for emissions and basic diagnostics. A plethora of OBD2 scan tools are available, with common examples being ELM327 or ELM329 based on programmed microcontrollers. The development of standard OBD2 continues, but access to advanced systems such as Driver Assist Systems often remains outside its scope. For deeper diagnostics, especially on a Mercedes-Benz, more specialized tools are necessary.

The Necessity of Multiplexers and Advanced Aftermarket Equipment

To overcome the limitations of standard OBD2, the aftermarket has developed a range of tools, including multiplexers, that claim to offer “complete access” to a vehicle’s diagnostic port, encompassing all internal networks and sub-networks. Unlike basic OBD2 devices, these advanced multiplexers are designed to tap into the complete network architecture, provided their software and firmware are current and accurately developed. This access extends to permissions across all installed networks and their corresponding sub-networks. Comprehensive access should include the ability to interface with multiple CAN networks connected to a gateway that supports a multitude of networks and sub-networks.

However, these aftermarket solutions are not without their challenges. Issues regarding accuracy, the reliability of guided tests, and often insufficient or inadequate documentation are common. Bi-directional control and consistent future support can be inconsistent. Furthermore, the integration of workshop information with clear parts illustrations, and the coherent association of data across controllers and the Central Gateway (CGW) can be problematic. A more recent challenge for these tools is gaining access to the Ethernet structure, essential for vehicles employing Diagnostics over Internet Protocol (DoIP). This is where specialized systems like XENTRY become indispensable.

XENTRY: Stepping into Professional Mercedes-Benz Diagnostics

For Mercedes-Benz vehicles, XENTRY emerges as the definitive diagnostic solution. It transcends the limitations of generic OBD2 tools and many aftermarket multiplexers by providing deep, manufacturer-level access to vehicle systems. XENTRY is specifically engineered to communicate with all electronic control units (ECUs) within a Mercedes-Benz, offering capabilities far beyond basic fault code reading.

Previous articles have highlighted the versatility and power of XENTRY in a professional workshop setting. These resources emphasize XENTRY‘s performance and its role in executing complex diagnostic and repair tasks effectively:

- Newest Features of Versatile XENTRY Diagnostic System (March, 2016)

- The Intelligent Servo Module (December, 2016)

- Why You Need XENTRY (June, 2017 as a sidebar to Using WIS Efficiently)

- Control Unit Programming Now! (December, 2017)

These articles collectively underscore XENTRY’s ability to perform in-depth diagnostics, module programming, and adaptations, functionalities that are critical for comprehensive Mercedes-Benz servicing and far exceed what standard OBD2 scanners can achieve. When considering XENTRY OBD2 in the context of these capabilities, it’s clear that XENTRY leverages the OBD2 port as a gateway to its extensive diagnostic functions.

XENTRY OBD2 in Action: Diagnosing Communication Errors

To illustrate the power of XENTRY in real-world scenarios, let’s examine a case study involving a 2011 ML 350 BlueTec with a perplexing no-start issue. This case demonstrates how XENTRY, going beyond basic OBD2 functions, can effectively diagnose complex communication errors within the vehicle’s network.

Initial Symptoms and Challenges

The customer reported an intermittent no-start condition. Compounding the issue were several other symptoms: all warning lamps illuminated, a continuous warning chime, intermittent operation of the windshield wipers, and non-functional Direct Select with no display indication. The no-start issue recurred, prompting a thorough diagnostic investigation.

XENTRY Quick Scan and Initial Findings

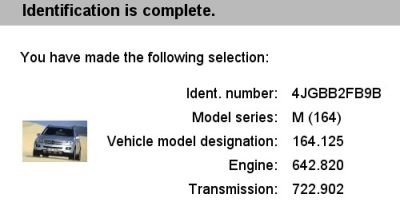

The diagnostic process began with a comprehensive “circle check” of the vehicle and testing of both batteries to rule out basic electrical issues. The diagnostic setup included ensuring XENTRY was updated and connecting a stable power supply to the vehicle. All unnecessary electrical consumers were turned off to minimize interference. Using XENTRY, the vehicle model was correctly identified via the VIN tab. A complete Quick Scan was then performed, and the initial results were carefully saved.

The initial XENTRY Quick Scan revealed a disruption within the vehicle’s network. Several controllers showed errors, including the Common Rail Diesel Injection, SCR-Selective Catalytic Reduction, Transmission, ESP (Electronic Stability Program), and Airbag systems. A deeper analysis indicated that multiple controllers were offline, suggesting a significant communication issue rather than isolated component failures.

Deep Dive with XENTRY and WIS

Further investigation with XENTRY, coupled with the Workshop Information System (WIS), became essential to pinpoint the root cause. A subsequent scan after initial diagnosis attempts revealed a list of controllers that were not communicating with XENTRY and were absent from the initial Quick Scan list. These included:

- ISM — Intelligent Servo Module

- IRS-HLA — Outer left rear intelligent radar sensor system

- IRS-HRA — Outer right rear intelligent radar sensor system

- XALWA-R — Xenon headlamp, right

- XALWA-L — Xenon headlamp, left

- RevETR-LF — Left front reversible emergency tensioning retractor

- RevETR-RF — Right front reversible emergency tensioning retractor

- ASSYST PLUS — Plus Active Service System

The fact that these controllers were not even being detected by XENTRY in the initial scans was a critical clue, indicating a profound network communication breakdown. XENTRY’s ability to highlight these missing controllers is a capability far beyond standard OBD2 scanners. The absence of Mercedes-Benz part numbers for these controllers in the scan data further suggested they were never fully interrogated or accessed by the diagnostic system during the initial scans.

Pinpointing the Faulty Component

Using XENTRY’s print feature, the entire initial scan document was saved for detailed review. The investigation focused on the primary scan data and the fault codes recorded. Attempts to reset controllers with communication errors directly through XENTRY proved unsuccessful, but these attempts provided valuable diagnostic information. A systematic approach to network reset was employed: disconnecting XENTRY and the power supply, removing the key, disconnecting the negative battery cable for 30 minutes, and then reconnecting everything for a repeat Quick Scan. Each scan session was meticulously recorded and saved within XENTRY.

To delve deeper into the communication issues, an oscilloscope was used in conjunction with XENTRY. By examining the CAN B and CAN C networks, it was possible to visually analyze the network signals. XENTRY and WIS were used to access network topology diagrams and wiring schematics to guide the oscilloscope testing.

By systematically disconnecting connectors on the CAN C network while monitoring the oscilloscope, a defective controller was isolated. The oscilloscope pattern normalized when a specific connector was removed, indicating that the fault was within the circuit connected to that point. XENTRY was instrumental in requesting and interpreting CGW (Central Gateway) coding data to further validate the network analysis. The CGW configuration, accessible through XENTRY, provided a detailed list of installed equipment and their communication status, helping to identify discrepancies and pinpoint the faulty module.

The combination of XENTRY’s diagnostic depth, WIS’s detailed information, and oscilloscope analysis led to the identification of a faulty Blind Spot Monitoring module as the “bad actor” disrupting the vehicle’s communication network. Disconnecting this module restored normal CAN network communication, as confirmed by both the oscilloscope and subsequent XENTRY scans.

A final XENTRY Quick Scan after disconnecting the faulty module showed a significantly reduced fault list, with only the disconnected Blind Spot Monitoring module reported as missing. Crucially, all other vehicle functions returned to normal, resolving the customer’s initial complaints.

XENTRY and WIS: A Powerful Combination for Mercedes-Benz Diagnostics

This case study underscores the synergistic power of XENTRY and WIS for diagnosing and resolving complex issues in Mercedes-Benz vehicles. While OBD2 provides a foundational level of diagnostics, systems like XENTRY are essential for accessing the full depth of vehicle electronics, especially when dealing with intricate network communication problems. WIS complements XENTRY by providing technicians with the necessary schematics, repair procedures, and component information to effectively utilize XENTRY’s diagnostic capabilities.

Benefits of Using XENTRY OBD2 for Mercedes-Benz

Choosing XENTRY OBD2 for Mercedes-Benz diagnostics offers numerous advantages:

- Manufacturer-Level Access: XENTRY provides unmatched access to all Mercedes-Benz vehicle systems, far exceeding the capabilities of generic OBD2 tools.

- Comprehensive Diagnostics: From basic fault code reading to advanced functions like module programming, adaptations, and detailed network analysis, XENTRY covers the entire spectrum of diagnostic needs.

- Guided Diagnostics and Tests: XENTRY often includes guided diagnostic procedures and tests, streamlining the troubleshooting process and improving diagnostic accuracy.

- Integration with WIS: The seamless integration with WIS provides technicians with essential repair information, schematics, and procedures, making XENTRY a complete diagnostic and repair solution.

- Enhanced Efficiency and Accuracy: By providing deep insights and manufacturer-approved procedures, XENTRY helps technicians diagnose and repair Mercedes-Benz vehicles more efficiently and accurately, reducing guesswork and minimizing repair times.

Conclusion: Embracing XENTRY for Mercedes-Benz Diagnostic Excellence

For workshops specializing in Mercedes-Benz vehicles, investing in XENTRY OBD2 systems is not just an option but a necessity. It equips technicians with the tools needed to tackle the increasing complexity of modern automotive systems, ensuring accurate diagnoses and effective repairs. While OBD2 serves as a universal starting point, XENTRY elevates diagnostic capabilities to the manufacturer level, unlocking the full potential for servicing and maintaining Mercedes-Benz vehicles to the highest standards. Explore the range of XENTRY OBD2 solutions available at xentryportal.store to enhance your diagnostic capabilities and ensure your shop remains at the forefront of Mercedes-Benz service excellence.